Benefit from our many years of experience in wet cleaning and discover the advantages of our flexible and modular cleaning systems. We have been successfully developing cleaning methods and process systems for a wide range of industries for over 30 years. We work closely with you, because nobody knows your needs better than you. We then manufacture your systems in Germany with the utmost care and precision - perfectly tailored to your requirements.

Whether for the food, cosmetics or aerospace industry - we have the right complete solutions that are precisely tailored to the needs of your products. We are particularly proud of our expertise in GMP-compliant cleaning in accordance with FDA and GAMP guidelines. This also makes us the ideal partner for the pharmaceutical industry.

Basic & concept development

Recording specific cleaning tasks

Carrying out cleaning tests and analyses

Process selection and process design

Support with tender documents (URS)

Demand-oriented offer preparation

Project management

Process engineering

Detail engineering

System documentation in accordance with CE directives

Automation

Production & Factory Acceptance Test (FAT)

SERVICES ON SITE

Installation and assembly

Commissioning on site

Acceptance test ready for operation (SAT)

Qualification

- Design Qualification (DQ)

- Creating IQ and OQ documents

- Support with qualification and validation

- Support with the PQ

Service

- Maintenance and servicing

- Retrofits

- Spare parts management

- Training courses

Modular cleaning systems that meet your requirements

Modular cleaning systems that meet your requirements

Our modular single and multi-chamber systems offer flexible internal and external cleaning for a wide variety of wash items - from containers and drums to pallets. Thanks to innovative multi-purpose systems, a wide range of requirements can be combined in a single cleaning concept. Our high-performance drum washers offer first-class efficiency and reliability, especially for high volumes.

Modular construction kit

Single & multi-chamber systems

Personal protection cabin

Cleaning, drying & cooling chamber

Centralized & decentralized media supply

Dosing station

Transportation system

Automation

Door & interlock system

Automation solutions that ensure a smooth process

Automation solutions that ensure a smooth process

We offer specialized automation technology for various key areas and develop software solutions that fit your industrial processes. Of particular importance to us are user-friendly visualization systems that make it easier to monitor your cleaning and process equipment. We also rely on validatable control systems that meet the requirements of 21 CFR Part 11 to guarantee maximum reliability and compliance.

Our services at a glance

- Hardware and software planning (HDS SDS)

- Circuit planning with CAE ePLAN P8

- Programming and configuration of Siemens control systems

- Programming with SYMATIC STEP 7 in TIA Portal

User-friendly system operation and process visualization with Siemens WinCC

- User and password management

- Audit trail: detailed, chronological recording of all activities for process parameters and recipes

- MES system interfaces and connection

- cGAMP and 21 CFR Part 11 compliant automation

Flexible CIP systems that save time and resources

Flexible CIP systems that save time and resources

Our process ensures precise and reproducible cleaning procedures. With our flexible CIP systems, we adapt the cleaning processes to your individual requirements. Thanks to efficient programs and integrated heating systems, we noticeably shorten process times and thus increase efficiency. We work with you to develop the optimum process for the best possible cleaning result.

Another advantage: we can integrate several tanks on a modular basis to make your processes even more efficient and flexible.

- AP tank

- Return tank

- Holding tanks

- Detergent tank (inline dosing without tank possible)

- Inline dosing

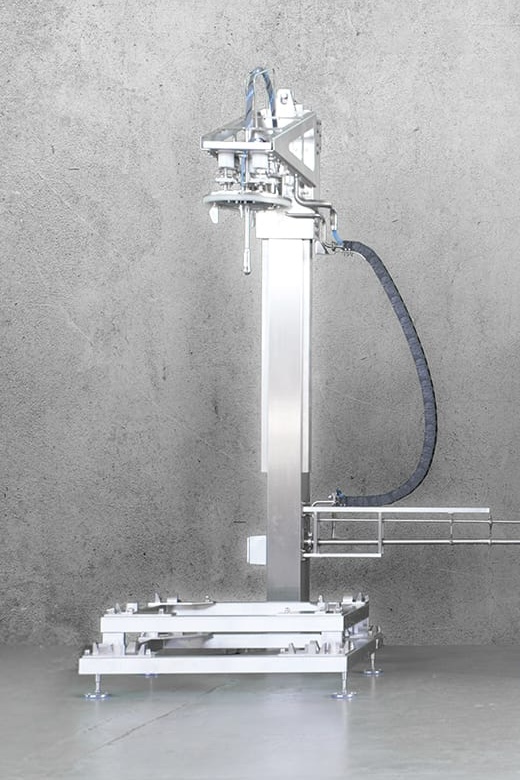

Interior cleaning with open washing systems

Interior cleaning with open washing systems

We also have a suitable solution for interior cleaning with our open and integrable washing systems. Our systems are easy to validate thanks to repeatable programs and our recipe management system allows you to effortlessly set the best washing results. We use modular technology to implement centralized and decentralized system solutions.

Various modules offer flexible configuration options:

Media preparation (CIP station)

Dosing station

Lifting column with movable internal cleaning

Interface plate with hose connections

Container holder

Manual external washing unit possible

We specialize in the cleaning of:

Container

IBC

Barrels

Preparation tank with controllable agitator

Other cleaning systems that master every challenge

High-quality products require customized solutions. Thanks to our many years of experience in special system construction, we have already successfully mastered many different cleaning tasks. You can therefore rely on our experienced team and our efficient cleaning systems, even for the most demanding challenges.

SMALL PARTS CLEANING SYSTEMS

Our compact small parts cleaning systems are specially designed to reproducibly clean production equipment such as buckets, cups and tools as well as format parts from tableting and other production machines. Every detail counts, especially with contaminated components. This is why our specially developed washing baskets and carriers can be individually adapted and planned.

- Filter

- Pallets

DRYING SYSTEMS

We specialize in drying systems that are particularly suitable for radioactive waste. In this sensitive area, we attach great importance to precisely understanding and taking into account the individual requirements of our customers.

- Circulating air or contact dryer with or without vacuum evaporation

- One/two or multiple drum drying systems